Louver automatic backwashing filter

The dryness requirement can realize filter cake pressure drying, adding liquid pulping after leaving no residual liquid, and pressing it back into the container for secondary use. The unique filter element skeleton design is twice the area of the traditional filter machine. If the process needs concentration, its clear liquid flow rate is very fast. The solid particles are backflushed back into the liquid and the thickened slurry is discharged intermittently or continuously without stopping the filtration.

Classification:

Louver automatic backwashing filter

Key words:

Louver automatic backwashing filter

Product accessories:

Product Details

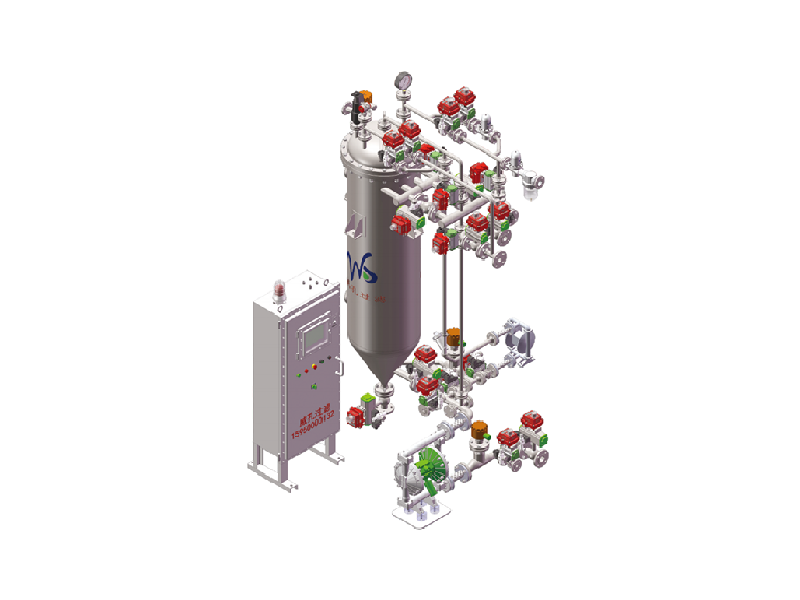

WKT Series (Press Dry and Wet)

Filter characteristics

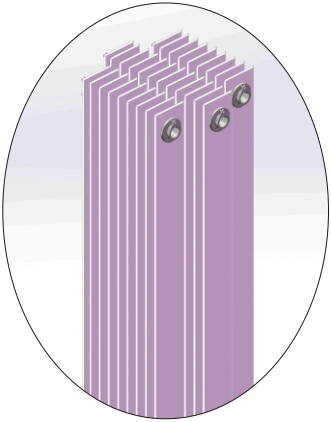

The dryness requirement can realize filter cake pressure drying, adding liquid pulping after leaving no residual liquid, and pressing it back into the container for secondary use. The unique filter element skeleton design is twice the area of the traditional filter machine. If the process needs concentration, its clear liquid flow rate is very fast. The solid particles are backflushed back into the liquid and the thickened slurry is discharged intermittently or continuously without stopping the filtration.

1. Completely closed high security system, no liquid and odor leakage

2. Automatic filtration, no manual

3. Fast filtration speed and low filtration cost

4. Use atomized spray technology to press dry the filter cake without leaving residual liquid

5. Ensure the integrity of each batch

6. To slag purification, improve product quality

7. a variety of materials a variety of precision filter cloth can be selected

8. The regeneration effect of filter cloth back blowing is the same as before.

9. The anti-corrosion performance of the equipment fully meets the requirements

Previous Page

Next Page

Previous Page

Next Page