Louver automatic backwashing filter

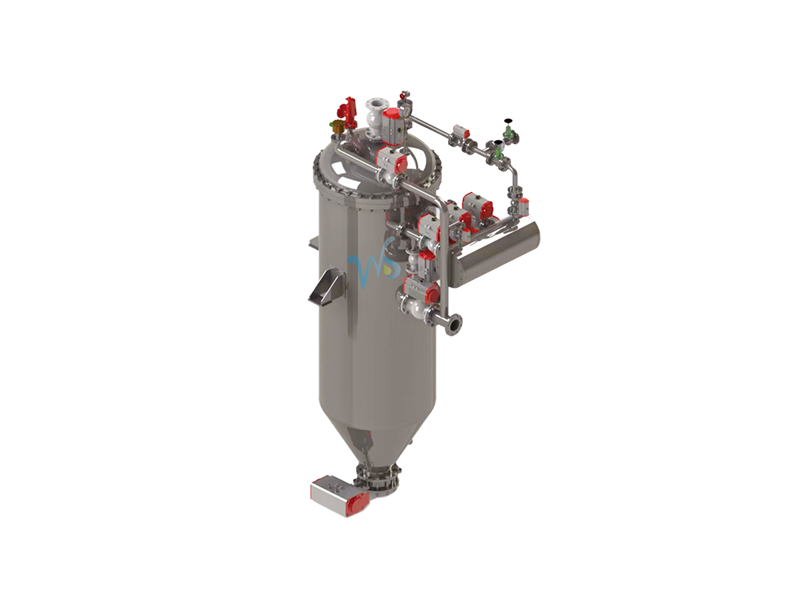

WKV solid-liquid separation process. It is required to be fully sealed without leakage of liquid and odor. No dryness requirements, particles are often suspended in a large amount of feed liquid resulting in low particle concentration, the need to deal with this type of feed liquid will be a large filter area. The filtration equipment has a small physique, which reduces the factory floor area and greatly reduces the investment cost.

Classification:

Louver automatic backwashing filter

Key words:

Louver automatic backwashing filter

Product accessories:

Product Details

WKV series (concentrated)

The filtration pressure is generally low in 0.05~0.25MPa.

2. Filtration temperature 1-120 ℃.

3. A variety of materials, a variety of precision filter cloth can be selected.

4. The filtration precision is high, and the suspended substance of the clear liquid after filtration is less than 20ppm.

5. Coating filtration can be added.

6. Filter cloth gas-liquid blowback (chemical) regeneration effect as before.

7. High degree of automation, simple operation: the whole process of all PLC automatic control, without special care.

8. Chemical stability, PH = 0.1~14, acid, alkali, salt solution has good chemical stability.

9. Equipment material: 304,316L,2205, compound 904L,C276, lined with PTFE, rubber, plastic.

WKV series

Industrial wastewater purification, water reuse, water resources recycling

Weikong Filtration Technology Co., Ltd. has established cooperative relations with many domestic companies. The core product solid-liquid separation filter has been used in non-ferrous smelting, fine chemicals, electronic products, fertilizers, rare earths, pharmaceuticals, pesticides, petroleum, environmental governance, and recycling Valuable solid and wastewater treatment and other fields have cooperated with many companies. We have been working hard to bring the greatest benefits to our customers and save energy and reduce emissions.

WKV solid-liquid separation process. It is required to be fully sealed without leakage of liquid and odor. No dryness requirements, particles are often suspended in a large amount of feed liquid resulting in low particle concentration, the need to deal with this type of feed liquid will be a large filter area. The filtration equipment has a small physique, which reduces the factory floor area and greatly reduces the investment cost.

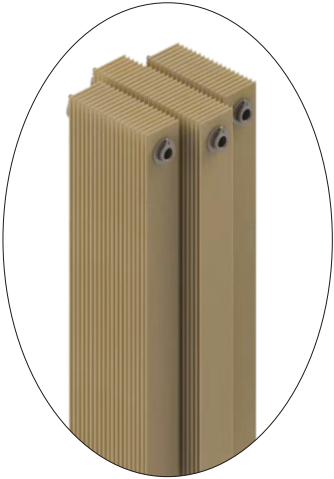

WKV concentration filtration technology. Provides intelligent solutions for filters. The unique design of the filter element skeleton, plus filter components supporting the use. The filter element frame arranged inside the filter provides a large filter surface area for a compact filter space. The internal space of the filter and the filter surface area are three or four times larger than ordinary.

If the process requires a concentrate filter, its clear liquid flow rate is very fast. The solid particles are backflushed back into the liquid and the thickened slurry is discharged intermittently or continuously without stopping the filtration. It can be filtered in one group and backwashed in one group to ensure uniform hydraulic distribution when providing gas-liquid backwashing. It also solves the problem of filter cloth blockage and the mud cake falls off quickly.

Successful application

Before entering reverse osmosis and RO membrane, slag removal, precision filtration of production water, river water, well water and tap water, reuse of reclaimed water, filtration of washing water and cooling water, filtration of deflowing amine liquid to remove activated carbon used to adsorb foaming substances to avoid loss and pollution of amine liquid, and treatment of chemical wastewater. Electroplating wastewater, circuit board wastewater. Battery wastewater, mine wastewater, wastewater containing sulfuric acid, vanadium liquid purification wastewater, fertilizer wastewater, dilute phosphoric acid wastewater, fluoride wastewater, fluorosilicic acid solution wastewater, soot wastewater, oilfield water injection, metallurgical wastewater, smelting wastewater, coal yard wastewater, heavy metal wastewater. Iron ore tailings acid leaching after arsenic removal of rinse water, new energy wastewater and other wastewater fine filtration

Previous Page

Previous Page

Next Page