Microporous membrane filter

Wide chemical compatibility, large circulation, low pressure difference and long service life. Wide range of filtering accuracy, large selection, can meet a variety of applications. The use of hot melt process, firm and no release of pollution products. It can be cleaned by common methods and sterilized by high pressure disinfection cabinet and steam.

Classification:

Microporous membrane filter

Key words:

Microporous membrane filter

Product accessories:

Product Details

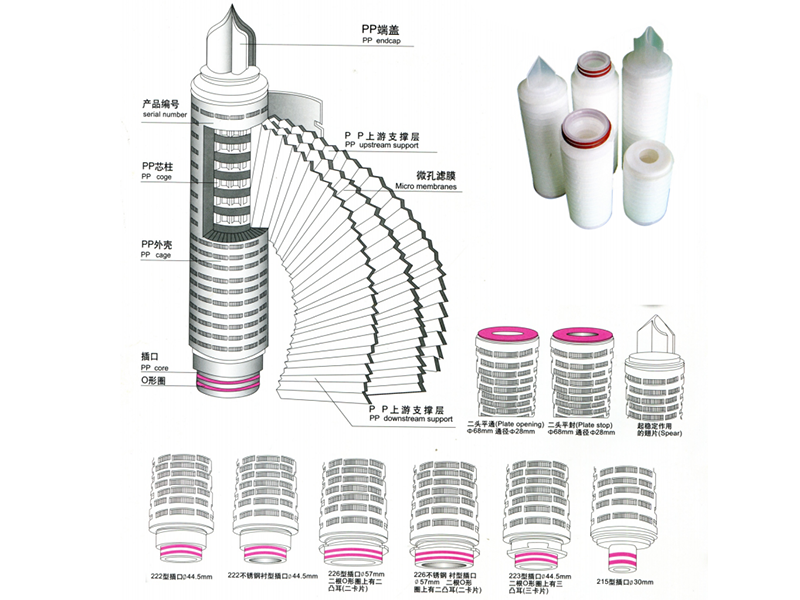

Folded microporous membrane filter element

|

Filter Element Length (inches) |

40" |

30" |

20" |

10" |

5 |

|

100 |

75 |

50 |

25 |

12.5 |

Note: Filter aperture 0.22 0.45 1 3 5 10 20

Folded polypropylene membrane filter element uses polypropylene membrane (Polyproplene) as the main filter material.

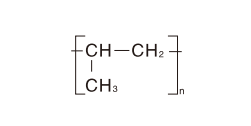

Polypropylene (HPP) microporous filtration membrane Chemical structure:

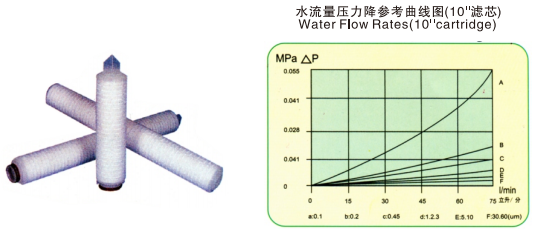

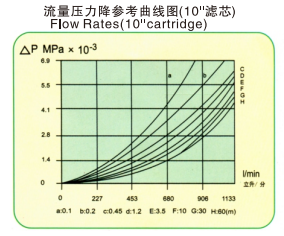

The folded polypropylene membrane filter element is an advanced fixed deep filter element with a nominal filtration accuracy ranging from 0.1μm to 60μm. The filtration membrane is not affected by feed pressure fluctuations and filtration accuracy. Its unique low pressure difference, high throughput, good filtration accuracy and low economic costs to replace the wire wound, cotton cake and cardboard and other non-fixed filter element and welcomed by users.

Main characteristics

Wide chemical compatibility, large circulation, low pressure difference and long service life. Wide range of filtering accuracy, large selection, can meet a variety of applications. The use of hot melt process, firm and no release of pollution products. It can be cleaned by common methods and sterilized by high pressure disinfection cabinet and steam.

Typical use

Electronic industry: reverse osmosis water system pre-filtration, deionized water system pre-over.

Food industry: beverage, wine, mineral water, pure water and other filtration.

Chemical industry: organic solvent, ink and other filtration.

Pharmaceutical industry: filtration of pharmaceutical, biological and plasma products, filtration of compressed air and gases.

Others: plating solution, metal cutting solution, photosensitive resist and magnetic media filtration, etc.

Previous Page