Full-automatic microporous filter without residual liquid

No dryness requirement for filter residue; Completely closed filtration, no leakage, safe production, no odor, no environmental pollution; The filter element is designed with PTFE microporous filter tube, which has a long service life and greatly reduces the operating cost. PTFE microporous filter tube, particles above 0.3 microns are filtered at one time.

Classification:

PE microporous filter

Key words:

Full-automatic microporous filter without residual liquid

Product accessories:

Product Details

Product Introduction

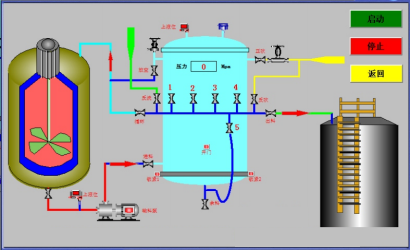

1. There is a requirement for the dryness of the slag, and the design realizes the filtration of no residual material.

2. As long as you press the control button lightly, the slag discharge port can be opened automatically, and the filter slag can be easily removed automatically.

3. The filtrate and filter residue can be recovered together.

4. PTFE micropores pass through the tube, and particles above 0.3 microns are filtered once.

5. PTFE temperature resistance 200 ℃

6. The rapid pressure drying system can be used to regenerate the filter tube with gas backflushing.

7, completely closed filter without leakage, safe production, no smell without any environmental pollution.

8, long life use. Greatly reduce operating costs.

9, the entire process can be fully automated.

Filter material

Q235, 304, 316L, 2205, 904, TA2, can be lined with anti-corrosion plastic, rubber, PTFE.

Scope of application

Fine chemical, pharmaceutical and food production in the batch of strict requirements of precision filter, activated carbon decolorization filter, catalyst, microfiltration of ultra-fine crystals.

WKB series technical parameter table

|

Model |

WKB-2 |

WKB-3 |

WKB-5 |

WKB-8 |

WKB-10 |

WKB-20 |

WKB-30 |

WKB-40 |

WKB-60 |

WKB-80 |

WKB-100 |

|

Body Material |

304/316L/Q235 lined with PO, rubber, PTFE |

||||||||||

|

Filter area (㎡) |

2 |

3 |

5 |

8 |

10 |

20 |

30 |

40 |

60 |

80 |

100 |

|

Processing capacity (T/h) |

According to the experimental data of specific materials |

||||||||||

|

Working pressure (MPa) |

≤ 0.25 |

||||||||||

|

Working temperature (℃) |

≤ 80-110 |

||||||||||

|

Body diameter (mm) |

Ø300 |

Ø300 |

Ø550 |

Ø600 |

Ø800 |

Ø900 |

Ø1000 |

Ø1400 |

Ø1600 |

Ø1800 |

Ø2000 |

|

Body height (mm) |

1500 |

1650 |

2400 |

2600 |

3100 |

3100 |

3700 |

4100 |

4100 |

4600 |

5200 |

|

Body volume (m³) |

0.057 |

0.071 |

0.297 |

0.367 |

0.754 |

0.954 |

1.178 |

2.31 |

3.5 |

4.0 |

4.8 |

|

Import and export caliber (mm) |

DN40 |

DN40 |

DN50 |

DN50 |

DN50 |

DN65 |

DN65 |

DN65 |

DN80 |

DN100 |

DN150 |

|

Slag discharge port (mm) |

Ø300 |

Ø300 |

Ø550 |

Ø550 |

Ø800 |

Ø800 |

Ø800 |

Ø800 |

Ø1600 |

Ø1800 |

Ø1800 |

No residual liquid

There are more than 1000 microporous filter machines in operation across the country.

Patent No.: ZL 2017 2 0876491.5

Patent No.: ZL 2017 2 1001111.X

Product Introduction

1, the filter residue has dry requirements, design to achieve no residual material filtration.

2. As long as you press the control button lightly, the slag discharge port can be opened automatically, and the filter slag can be easily removed automatically.

3. The filtrate and filter residue can be recovered together.

4. PTFE microporous filter tube, with particles above 0.3 microns filtered at one time.

5. PTFE temperature resistance 200 ℃

6, fast pressure dry system, available gas or steam blowback regeneration filter tube.

8. Completely sealed filter without leakage, safe production, no smell without any environmental pollution.

9, long life use, greatly reduce operating costs.

The entire filtration process can be fully automated.

Filter material

Q235, 304, 316L, 904, TA2, 2205, can be lined with anti-corrosion plastic, rubber, PTFE.

Patent number: ZL2017 21561454.1

Previous Page

Previous Page