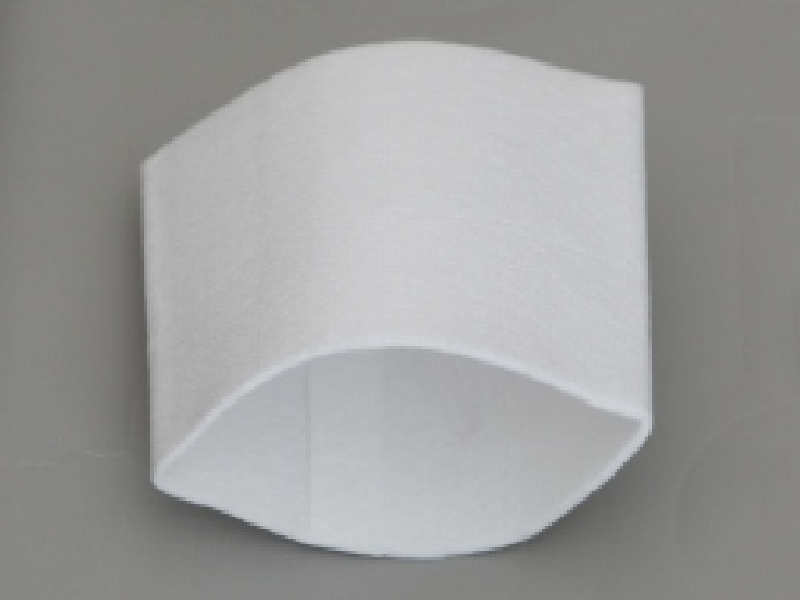

Filter cloth for candle filter

The filter function can efficiently recover the useful materials in the filtrate. The filter unit has no residual liquid design. The filtration of the material filter aid uses radial woven felt cloth or membrane with a pore size of less than 0.1 u m. It is tightly clamped at both ends of the filter unit to withstand axial recoil pressure. This structure can withstand high recoil pressure, so very fine filter cloth and membrane can be used without worrying about blocking. This provides a wide range of filter media options (there are hundreds of filter media to choose from). Full

Classification:

Candle filter

Key words:

Filter cloth for candle filter

Product accessories:

Product Details

|

Name |

Model |

Temperature |

Flattening width |

|

Stainless Steel |

316L |

650 ℃ |

140 /-2mm |

|

Teflon |

PTFE |

200℃ |

140 /-2mm |

|

Polyimide |

P84 |

240℃ |

140 /-2mm |

|

polyphenylene sulfide |

PPS |

190℃ |

140 /-2mm |

|

polyester polyester |

PE |

130℃ |

140 /-2mm |

|

Polypropylene |

PP |

90℃ |

140 /-2mm |

|

Polyetheretherketone |

PEEK |

260℃ |

140 /-2mm |

Online cleaning filter cloth

Online cleaning can extend the service life of the filter cloth. According to the requirements, the filter cloth can be automatically cleaned in a closed filter to remove particles that may adhere.

Unique filtering features

The filter function can efficiently recover the useful materials in the filtrate. The filter unit has no residual liquid design. The filter of the material filter aid uses radial woven felt cloth or a membrane with a pore size of less than 0.1 pu m. It is tightly clamped at both ends of the filter unit to withstand axial recoil pressure. This structure can withstand high recoil pressure, so very fine filter cloth and membrane can be used without worrying about blocking. This provides a wide range of filter media options (there are hundreds of filter media to choose from). Meet various separation process requirements.

Previous Page

Next Page

Previous Page

Next Page