The heart of the candle filter

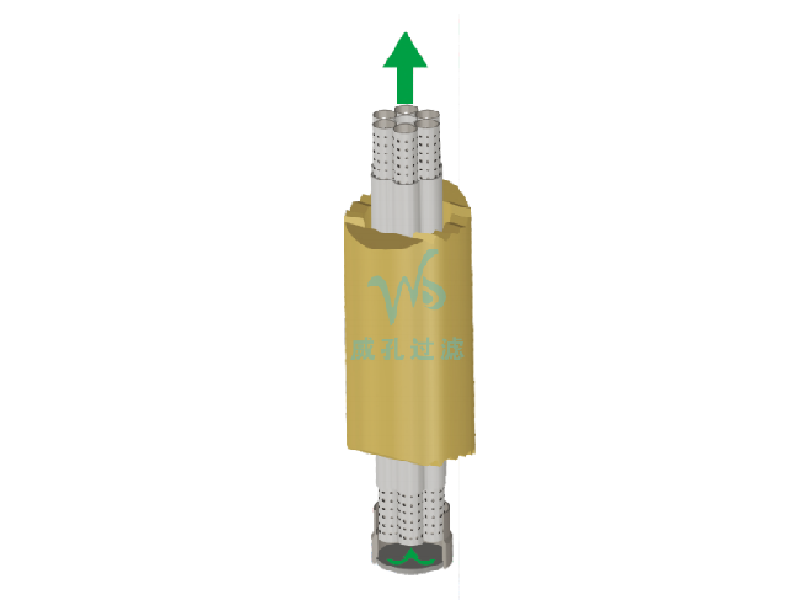

The filter function can efficiently recover the useful materials in the filtrate. The filter unit has no residual liquid design. The filter aid of the material is filtered. The radial woven felt cloth or the membrane with a pore size less than 0.1μm is used. It is tightly clamped at both ends of the filter unit to withstand axial recoil pressure. This structure can withstand high recoil pressure, so very fine filter cloth and membrane can be used without worrying about clogging. This provides a wide range of filter media options (there are hundreds of filter media to choose from). Meet various separation process requirements.

Classification:

Candle filter

Key words:

The heart of the candle filter

Product accessories:

Product Details

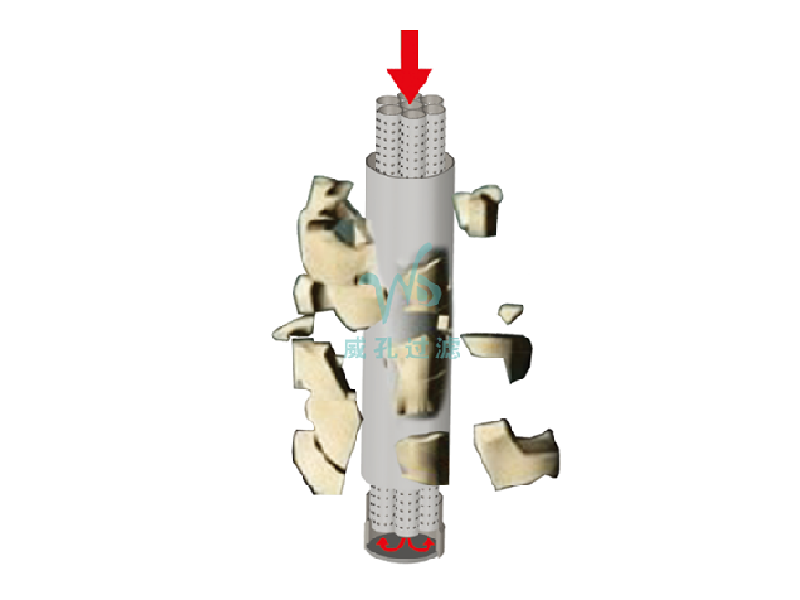

Formation of filter cake and backflushing of dried filter cake

1. Center tube clear liquid collection tube

2. The filter tube as the support of the filter medium

3. Typical filter tube openings

4. Filter media

5. Filter cake

6. The collection chamber is connected to the central tube and the filter tube.

7. The clear liquid leaves the filtration unit through the central tube

8. Blow back gas to promote filter cake discharge

1. A filter tube is installed around the riser tube. The filter tube is covered with filter material. Both ends of the filter material are clamped tightly with snap rings.

2. The stock solution entering the filter machine flows into the filter tube through the gap after passing through the filter material, and then is sent to the filter tube for recovery by the lift tube. The filter material is petal-shaped and forms filter cake on the surface under the pressure of the pump. In order to make the filter cake evenly attached to the filter material, the company has made in-depth research on the shape of the filter tube. In addition, due to the design of the lift tube, the filter cake will not fall of air pressure drop.

3. Material of filter element: 304, 316L, 904, 2205, rigid PP, PTFE, PVDF, TA2.

After the liquid in the filter has been emptied and the filter cake has been washed and dried, each filter unit will be backflushed with gas. As the filter media expands, cracks develop in the filter cake. When the medium expands to the maximum, the movement stops, the filter cake is thrown away from the medium, and the filter cake with a thickness of 3-50mm is completely discharged.

Previous Page

Previous Page

Next Page