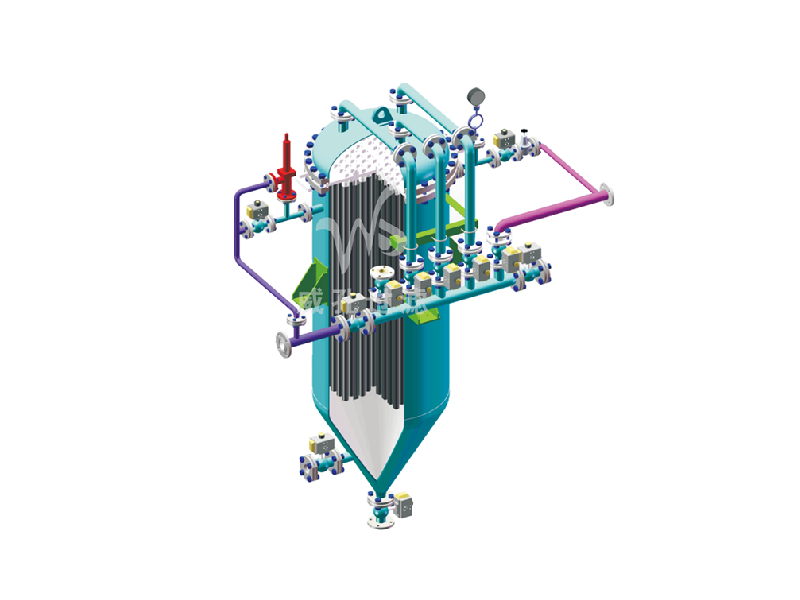

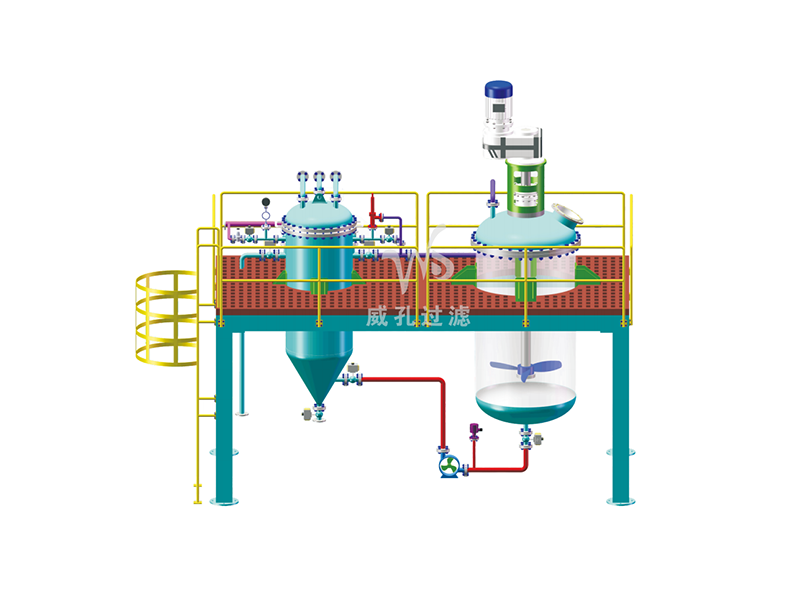

Automatic microporous concentration filter

No dryness requirement for filter residue; Completely closed filtration, no leakage, safe production, no odor, no environmental pollution; The filter element is designed with PTFE microporous filter tube, which has a long service life and greatly reduces the operating cost. PTFE microporous filter tube, particles above 0.3 microns are filtered at one time.

Classification:

PE microporous filter

Key words:

Automatic microporous concentration filter

Product accessories:

Product Details

Product Introduction

Product Introduction

1. There is no requirement for dryness of filter residue.

2, completely closed filter, no leakage safety production, no smell, no environmental pollution.

3, filter design using PTFE microporous filter tube, long life use, greatly reduce operating costs.

4. PTFE microporous filter tube, with particles above 0.3 microns filtered at one time.

5. PTFE temperature resistance 200 ℃

6. The filter tube can be regenerated by gas blowback.

7, slag clean and rapid, adapt to a variety of viscous materials.

The entire filtration process can be fully automated.

Filter material

Q235, 304, 316L, 2205, 904, TA2, can be lined with anti-corrosion plastic, rubber, PTFE.

Scope of application

Fine chemicals, mining, pharmaceutical, food, environmental protection, wastewater treatment, ceramic chlor-alkali, activated carbon decolorization and carbon filtration, porcelain, glass, metal catalyst, zeolite and other solid recovery.

WKA series technical parameter table

|

Model |

WKA-3 |

WKA-5 |

WKA-8 |

WKA-10 |

WKA-15 |

WKA-20 |

WKA-30 |

WKA-40 |

WKA-60 |

WKA-80 |

WKA-100 |

WKA-120 |

WKA-150 |

|

Body Material |

304/316L/Q235 lined with PO, rubber, PTFE |

||||||||||||

|

Filter area (㎡) |

3 |

5 |

8 |

10 |

15 |

20 |

30 |

40 |

60 |

80 |

100 |

120 |

150 |

|

Processing capacity (T/h) |

According to the experimental data of specific materials |

||||||||||||

|

Working pressure (MPa) |

≤ 0.25 |

||||||||||||

|

Working temperature (℃) |

≤ 80-110 |

||||||||||||

|

Body diameter (mm) |

Ø300 |

Ø500 |

Ø600 |

Ø800 |

Ø800 |

Ø900 |

Ø1000 |

Ø1200 |

Ø1200 |

Ø1400 |

Ø1600 |

Ø1800 |

Ø2000 |

|

Body height (mm) |

1200 |

2200 |

2300 |

2550 |

3000 |

3200 |

3200 |

3500 |

3500 |

3200 |

4500 |

5300 |

5500 |

|

Body volume (㎡) |

0.057 |

0.196 |

0.283 |

0.503 |

0.754 |

0.954 |

1.178 |

1.696 |

1.696 |

2.077 |

4.019 |

6.359 |

7.85 |

|

Import and export caliber (mm) |

DN40 |

DN40 |

DN65 |

DN65 |

DN65 |

DN65 |

DN65 |

DN65 |

DN65 |

DN65 |

DN65 |

DN80 |

DN80 |

|

Slag discharge port (mm) |

Ø300 |

Ø300 |

Ø300 |

Ø300 |

Ø300 |

Ø300 |

Ø300 |

Ø300 |

Ø300 |

Ø300 |

Ø500 |

Ø500 |

Ø500 |

Next Page